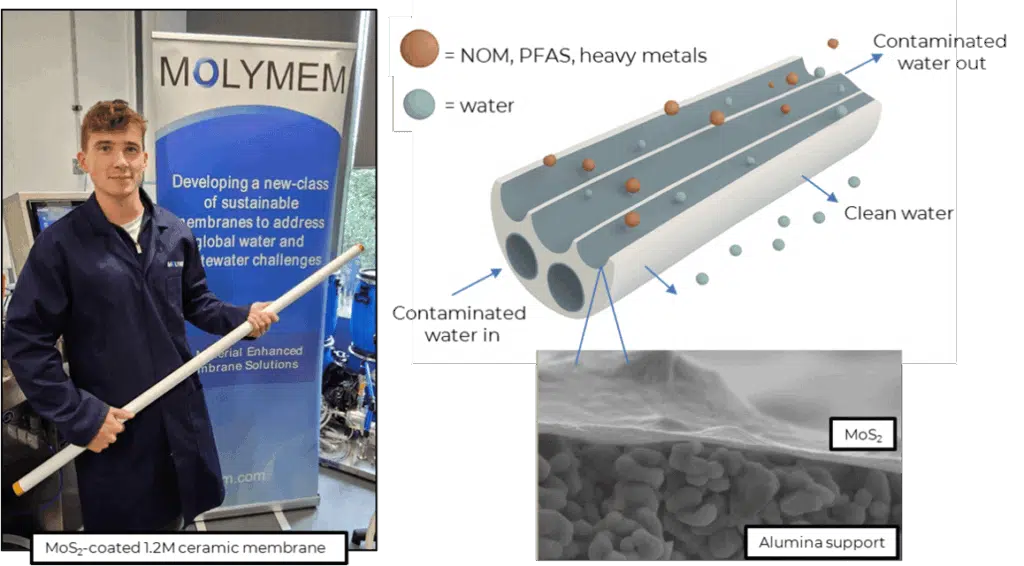

Molymem’s 2D molybdenum disulphide (MoS2) coating was applied to a 19-channel, 0.28m2 surface area ceramic to produce a 2D-ceramic nanofiltration membrane and tested on untreated moorland waters which are rich in NOM. The coating is scalable and can be applied to large area ceramic membranes of different geometries. This development represents a world first in realising the unique filtration and separation capabilities of 2D membranes at industry relevant scales.

Natural organic matter (NOM) is found in raw water and is known to react with the chlorine used in water treatment to produce disinfection by-products (DBPs), some of which are potentially harmful to human health due to their links with cancers.

Scottish Water operates over 100 Water Treatment Plants (“WTPs“) using polymer nanofiltration membranes for NOM removal, which are integral to drinking water production at small rural works. While effective for NOM removal, current polymers are difficult to chemically and mechanically clean which shortens membrane lifetime increasing treatment cost, with cost compounded by the high operating pressures required to push water through the membranes.

Conversely, ceramic membranes are an emerging technology less prone to fouling and are resistant to harsher chemical cleans, yielding longer operational lifetimes (typically 15 years). Despite these benefits seen in the microfiltration range, ceramic membranes have not been commercially realised in the nanofiltration range due to challenging manufacturing processes and high energy costs.

However, Molymem’s 2D coatings can readily convert existing ceramic membranes into ultrafiltration (“UF”) or NF membranes using a single, room-temperature deposition method that can be performed using standard filtration equipment. This couples the benefits of ceramic membranes with the selectivity needed to facilitate nanofiltration for NOM removal and the potential to access lower operating pressures due to the permeability inherent in MoS2 films.

In collaboration with Prof. Ewan McAdam, Professor of Membrane Science and Technology Cranfield Water Science Institute, Cranfield University and supported through an IUK Smart Grant, Molymem coated ceramic membranes were benchmarked against industry standard, reg-31 approved, polymer NF membranes (2000Da MWCO) for the removal of NOM and assess differences in DBP formation potentials.

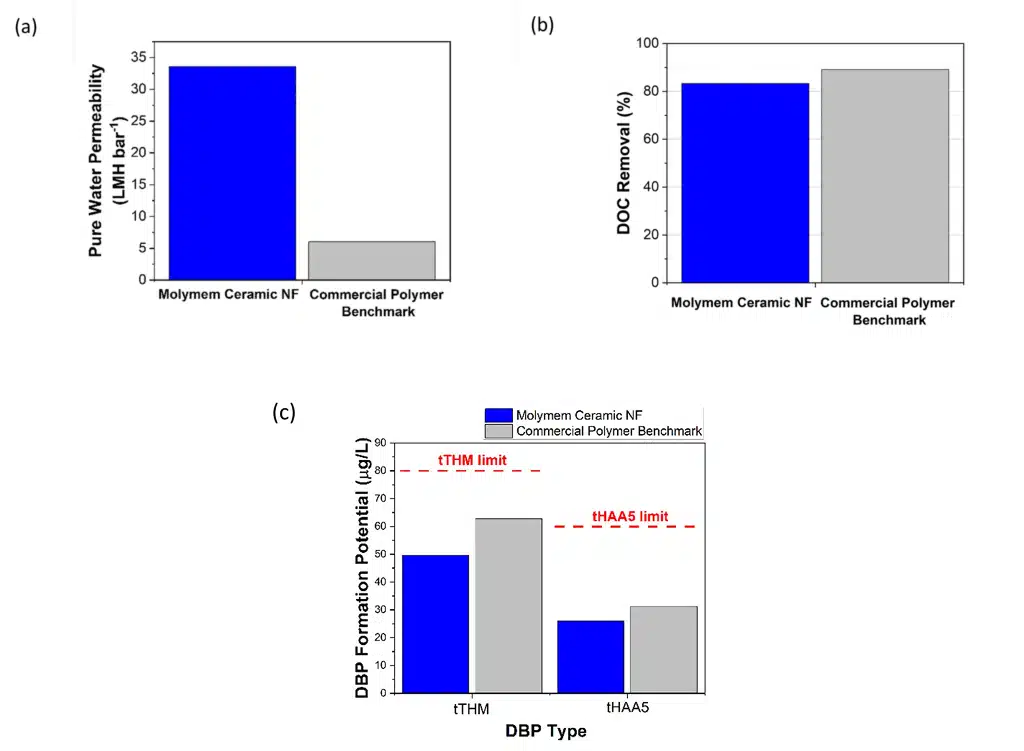

Fig 1 shows the preliminary pure water permeation, dissolved organic carbon (DOC/NOM) rejection (the precursor to DBP formation) and DBP formation potentials as a function of a Molymem ceramic vs. a 2000Da MWCO polymer membrane. First generation Molymem ceramic membrane chemistry exhibited significantly higher water permeation rates (4-5 times) whilst maintaining high DOC rejection behaviour compared to the polymer membranes. DBP formation potentials are well below the regulatory limits. Further testing shows that the coating is also stable in harsh acidic and basic conditions and maintains stable performance over more than a 700-hour operational window.

Figure 1. Molymem Ceramic NF performance vs a commercial polymer benchmark. Water tested: Upland Scottish Water, ~7.0 ppm DOC, pH 6.4. Membrane test conditions: 0.3 m/s crossflow velocity, 3 bar transmembrane pressure, 20 °C. Commercial benchmark is a 2000 Da MWCO polymer membrane. (a) Pure Water Permeability (b) DOC rejection and (c) DBP formation potentials. Dotted red lines represent EPA discharge limits for total trihalomethanes (tTHM) and haloacetic acids (tHAA5) in drinking water.

Due to the impending extension of regulatory standards to cover a broader range of disinfection by-products (e.g. Haloacetic acids), there is in interest from industry in delivering nanofiltration into lowland water sources, but this requires tighter pore sizes to remove lower molecular weight organics, which is not presently possible with regulatory approved ceramic membranes. Second generation Molymem chemistry formulations have therefore been developed to permit the tuning of molecular weight cutoff in this new class of membranes to resolve this and a range of contemporary challenges that the water sector is presently seeking to resolve (e.g. PFAS).

This development marks a major milestone for Molymem and the wider 2D materials community, showcasing the successful scaling and application of 2D membrane coatings to deliver competitive, next-generation, and sustainable ceramic membranes for water, wastewater, and desalination pretreatment markets.

References:

(1). Dan-Mihai Golea: 2013- 2019. “Robust natural organic matter removal from Scottish water sources of variable DOC content”

(2). Davidkova et al. ACS ES&T Water 2024 4 (11), 5002-5012